Achieving High Precision and Tight Tolerances with CNC Milling

Understanding Precision, Tolerances, and Surface Finish Capabilities in CNC Milling

CNC milling can get down to the micron level when it comes to accuracy, which is why so many industries rely on it for parts that need to be exactly the same every time they come off the machine. When we talk about precision in manufacturing, what we really mean is how consistently those parts measure up across different batches. Tolerances basically tell us how much variation is allowed before something becomes unacceptable. Today's CNC machines can produce surfaces so smooth they hit around Ra 0.4 microns or about 16 micro inches roughness average. That kind of finish looks almost like polished metal because these machines use sophisticated path planning software and have super sturdy frames that cut down on vibrations while cutting materials. The end result? Parts that not only meet exact size requirements but also look great too.

How High Precision and Dimensional Accuracy Define CNC Milling Applications

Aerospace and medical device manufacturing rely heavily on CNC milling because it keeps dimensions tight even when conditions get tough. Take turbine blades for instance they need airfoil shapes accurate down to about 0.0008 inches or roughly 0.02 millimeters just so they can perform properly in flight. The same goes for surgical tools which have to be super sharp along their edges, usually within around 0.001 inch tolerance (that's about 0.025 mm). Manual machining just doesn't cut it here since people naturally vary too much from one piece to another. That's why CNC machines are essential for making parts where precision literally means life or death.

Data Point: Tolerance Ranges Achievable with Modern CNC Milling Systems

| Material | Typical Tolerance Range | Critical Applications |

|---|---|---|

| Aluminum Alloys | ±0.0005" (0.0127 mm) | Aircraft structural components |

| Titanium | ±0.001" (0.0254 mm) | Medical implants |

| Engineering Plastics | ±0.005" (0.127 mm) | Insulating spacers |

These tolerances reflect advancements in closed-loop feedback systems and temperature-stable machining environments. High-speed spindles capable of up to 60,000 RPM reduce tool deflection, contributing to consistent accuracy across large batches.

Industry Paradox: When Higher Precision Demands Increase Costs Exponentially

Going past those ±0.0002 inch (about 0.005 mm) tolerances really starts eating into budgets. For every 10% we cut down on acceptable variation, costs jump around 35%. Why? Slower machine speeds, special tools needed, and all those extra checks while parts are still being made. Getting this kind of exactness takes anywhere from three to five times longer than regular machining does. So there's always this balancing act between getting super accurate parts and keeping production costs reasonable. Most engineers know this well enough to reserve those tight specs only for absolutely essential components. They'll stick with standard tolerances everywhere else because nobody wants to spend twice as much just to get marginally better results when it doesn't actually matter for most applications.

Machining Complex Geometries and Multi-Axis Part Designs

Why CNC Milling Is Suitable for Complex Geometries in Advanced Manufacturing

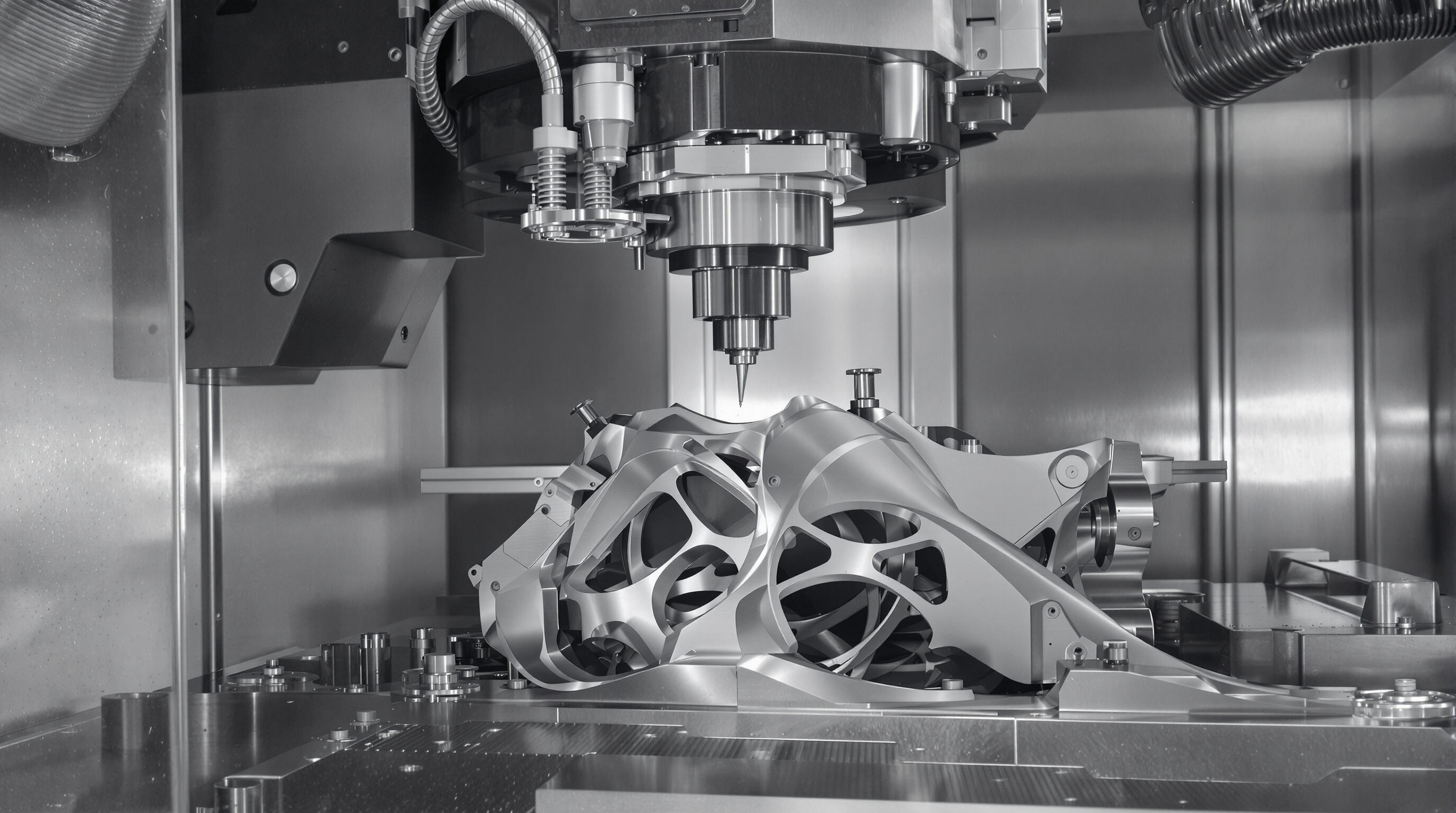

When it comes to making really complicated shapes that just can't be done with old school techniques, CNC milling stands out from the crowd. These machines basically read computer blueprints and cut parts with incredible precision, so they can reproduce all sorts of tricky features like curved surfaces, recessed areas, and those flowing organic shapes that would drive manual machinists crazy. For things like airplane parts or power plant components, most shops have jumped on board with 5-axis systems these days. According to recent industry data, around 96 percent of manufacturers now rely on this advanced setup to avoid having to do extra work steps after machining. What makes this tech so valuable is its ability to tackle both boxy, angular pieces and totally wild sculptural forms without sacrificing production speed or damaging the raw materials being worked on.

Role of 5-Axis CNC Milling Machines in Producing Intricate Part Designs

Five axis CNC milling machines work by moving along all five axes at once, giving cutting tools access to those tricky angles that regular three axis systems just cant reach. This kind of freedom makes a real difference for complicated parts such as aerospace impellers featuring those curved airfoil shapes. Machinists have found they can cut these components around 60 percent quicker while still hitting tight tolerances of plus or minus 0.01 millimeters. Factory floor reports from top manufacturers show something else too there are roughly 46% fewer mistakes during setup time compared to what happens with multiple steps needed on standard three axis machines. Less repositioning means less tool shaking as well, particularly important when working with delicate materials like thin wall aluminum or titanium alloys. Surface quality stays excellent throughout, often better than Ra 0.8 micrometers even after extended machining sessions.

Case Study: Milling Aerospace Components with Multi-Surface Contours

In a recent project, a titanium fuel nozzle featuring 37 internal cooling channels intersecting at non-orthogonal angles was produced using 5-axis contouring. Key outcomes included:

- 83% reduction in setups (from 12 to 2 operations)

- 0.025 mm positional accuracy across all channel exits

- 14-hour total machining time vs. 26 hours with 3-axis

The component successfully passed aerodynamic testing at Mach 2.4 conditions, demonstrating CNC milling's ability to combine geometric complexity with flight-certified reliability.

Material Versatility Across Industrial Applications

Modern CNC milling systems process materials ranging from aerospace-grade titanium (6Al-4V) to medical-grade PEEK polymers, meeting 92% of industrial material requirements (Advanced Manufacturing Report 2023). This adaptability allows manufacturers to serve diverse sectors without investing in dedicated machinery for each material type.

How Material Versatility in CNC Milling Supports Diverse Industrial Needs

CNC milling can handle well over fifty different materials thanks to adjustable cutting settings and smart tool path planning. Car makers regularly work with cast iron for engine blocks while also machining aluminum intake manifolds. Meanwhile hospitals rely on the same machines to create stainless steel surgical instruments as well as nylon prosthetic parts. A recent study from 2023 found that almost seven out of ten manufacturers saved between 18 and 22 percent on costs when they combined multiple material productions using CNC technology. This approach not only makes things run smoother but cuts down on those frustrating equipment changeovers that eat into productivity.

Processing Metals, Plastics, and Composites Using CNC Milling Techniques

Material-specific techniques optimize results:

- Metals: Use high-speed steel (HSS) tooling with flood coolant for titanium to manage heat buildup

- Plastics: Employ compression milling with <30° helix angle cutters to prevent edge melting

- Composites: Apply diamond-coated end mills at 1,200–1,500 SFM when machining carbon fiber to reduce delamination

This versatility supports integrated fabrication of multi-material assemblies, such as sensor housings combining aluminum bases, PEEK insulation, and stainless steel connectors—all completed in a single production sequence.

CNC Milling in High-Stakes Industries: Aerospace, Automotive, and Medical

Critical Components Produced via CNC Milling for Aircraft and Spacecraft

CNC milling makes some really important parts for aircraft, stuff like turbine blades, engine mounts, and various structural components of the airframe. The materials used here tend to be these special lightweight alloys such as titanium and aluminum. Machinists can get tolerances down to around 0.001 inches or better, which means these parts hold up when exposed to intense heat and physical forces during flight operations. For things like fuel delivery systems and landing gear where the shapes inside are super complicated, CNC machines repeat the same process over and over with incredible consistency. This kind of precision isn't just about making pretty parts it's actually critical for keeping planes safe and meeting all those strict aviation regulations that govern every aspect of aircraft manufacturing.

Meeting Stringent Safety and Performance Standards in Aerospace

Components used in aerospace manufacturing need to meet strict FAA and ESA regulations for safety and performance. CNC milling can produce surface finishes under Ra 8 microns, which makes parts last longer under stress and cuts down on air resistance during flight. The multi-axis capability of modern CNC machines means no need for constant manual adjustments when machining parts. This is especially important for things like satellite housings and rocket engine parts where even small mistakes can have big consequences. Fewer human interventions during production naturally leads to better quality control across the board.

Enhancing Production Efficiency with CNC Milling for Engine and Transmission Parts

Car makers rely on 5 axis CNC milling machines when they need to crank out engine blocks, transmission gears, and those suspension parts that hold everything together. The really tight tolerances here are around plus or minus 0.0005 inches, which makes all the difference for getting good seals in fuel injectors and making sure power gets transferred properly through the drivetrain. What's interesting is how one setup can actually handle cylinder heads too, keeping those valve seats within about 0.002 inches of concentricity. This saves shops loads of time compared to older techniques, probably somewhere around 40% faster according to what most shops report after switching over.

Producing Implants and Surgical Tools Requiring Biocompatible Materials and Precision

Doctors rely on medical grade titanium and PEEK materials when creating custom spinal cages, dental abutments, and various surgical tools, all manufactured to within 25 microns of precision. The CNC milling process creates surfaces so smooth they don't trap bacteria or other contaminants, which is absolutely critical for anything going inside the body. Surgeons get scalpels and bone rasps made with cutting edges at around 8 to 12 degrees angle, something that makes a big difference in minimizing damage to surrounding tissues during operations. Most stats show that about 96 percent of these machined implants pass FDA tests for being safe inside humans. No wonder then why so many hospitals still turn to CNC machining as their go to method for making those super precise medical devices we need today.

Rapid Prototyping and Low-Volume Production Advantages

The Role of CNC Milling in Rapid Prototyping Workflows

CNC milling really speeds things up for prototyping when it comes to turning those CAD designs into actual working models in just one to two days. Engineers get to check out how everything fits together, test the geometry, and see how the parts behave mechanically much earlier in the design process. They work with solid, fully dense materials like aerospace grade aluminum, some tough plastics that stand up to heat, and various composite materials. The big difference compared to 3D printing is that these CNC machined prototypes have exactly the same material characteristics as what will be used in mass production. That means companies get real performance data on hand well before they start making thousands of units, which saves time and money down the road.

Comparative Advantage Over 3D Printing for Functional Prototypes

3D printing definitely wins when it comes to quick turnaround times for simple shapes, but when we need something that actually works under stress, CNC milling takes the lead. The machines can hit those really tight tolerances around ±0.005 to 0.01 mm while maintaining solid structural integrity. Some research from last year showed just how much better CNC milled parts perform too – tests revealed they could handle about 120% more compression force compared to similar parts made with SLA printing methods. Because of this superior performance, many manufacturers turn to CNC machining for parts that need to bear weight or endure pressure. Think about car suspensions or housing units for medical equipment where getting the mechanics right isn't just important, it's absolutely critical for safety and functionality.

Workflow Insight: From CAD Design to G-Code Execution in CNC Milling Setup

When it comes to manufacturing workflows, the process typically begins with optimizing CAD models so they can actually be made in real life. Designers need to think about how tools will reach different parts of the model and whether certain features are too deep to work with standard equipment. Once the design is ready, CAM software takes over to create the G-code instructions. The settings here matter a lot - spindle speeds usually range from around 8,000 to 25,000 RPM depending on what's being cut. Feed rates vary too; Delrin material generally needs something like 300 to 500 mm per minute, whereas stainless steel works better at slower speeds between 150 and 250 mm per minute. What makes this whole system valuable is that even when producing small batches of 50 to 500 units, each piece comes out consistently good quality. This setup really helps manufacturers move smoothly from testing prototypes to making products at scale without losing that initial level of precision.

FAQs

What is CNC milling?

CNC milling is a computer-controlled machining process that involves using rotary cutters to remove material from a workpiece to achieve precise dimensions and surface finishes.

Why are tight tolerances important in CNC milling?

Tight tolerances ensure that the finished product meets exact specifications, which is critical in industries where component precision affects performance and safety, such as aerospace and medical device manufacturing.

How does 5-axis CNC milling differ from 3-axis milling?

5-axis CNC milling allows the cutting tool to move along five different axes simultaneously, enabling the machining of complex geometries and intricate part designs that 3-axis systems cannot handle.

What materials can be processed using CNC milling?

CNC milling can process a wide range of materials, from metals like aluminum and titanium to plastics and composites, making it adaptable for various industrial applications.

What are the advantages of CNC milling in rapid prototyping?

CNC milling allows for the quick production of prototypes with properties similar to the final product, providing more accurate data on performance before mass production begins.

Table of Contents

-

Achieving High Precision and Tight Tolerances with CNC Milling

- Understanding Precision, Tolerances, and Surface Finish Capabilities in CNC Milling

- How High Precision and Dimensional Accuracy Define CNC Milling Applications

- Data Point: Tolerance Ranges Achievable with Modern CNC Milling Systems

- Industry Paradox: When Higher Precision Demands Increase Costs Exponentially

- Machining Complex Geometries and Multi-Axis Part Designs

- Material Versatility Across Industrial Applications

-

CNC Milling in High-Stakes Industries: Aerospace, Automotive, and Medical

- Critical Components Produced via CNC Milling for Aircraft and Spacecraft

- Meeting Stringent Safety and Performance Standards in Aerospace

- Enhancing Production Efficiency with CNC Milling for Engine and Transmission Parts

- Producing Implants and Surgical Tools Requiring Biocompatible Materials and Precision

- Rapid Prototyping and Low-Volume Production Advantages

- FAQs