Precision and Dimensional Accuracy in CNC Machined Parts

Understanding Tolerances and Dimensional Accuracy in CNC Parts

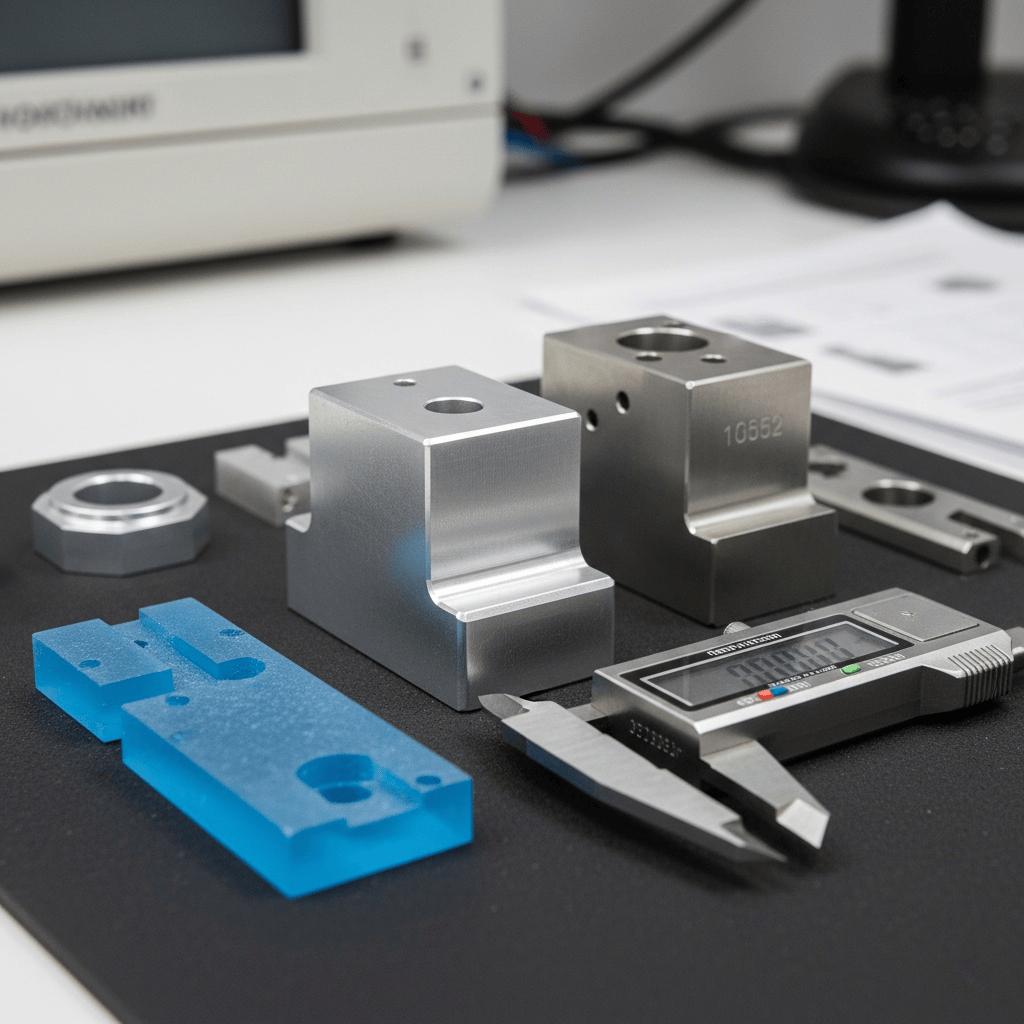

Tolerances basically tell us how much a part can vary in size before it stops working properly. These days, modern CNC machines can get really precise, sometimes hitting tolerances as small as plus or minus 0.001 inches which is about 0.025 millimeters. This kind of precision matters a lot in things like medical equipment where even tiny differences matter, or in parts used in airplanes. When parts fit together tightly because of good tolerances, there are fewer gaps between them, so they don't wear down as fast and distribute forces better across surfaces. But going too far with super tight specs isn't always smart either. According to Pinnacle Metal from 2025, pushing for extremely tight tolerances can actually slow down production and raise costs by around 30%. Finding the right balance between precision and practicality remains key if manufacturers want to keep their operations both effective and affordable.

The Role of Geometric Dimensioning and Tolerance (GD&T) in Part Functionality

The GD&T standards such as ASME Y14.5 basically tell manufacturers how different parts fit together when they're assembled. Take hydraulic pump shafts for instance these need really tight concentricity controls around 0.005 millimeters or less to stop fluids from leaking out when pressures get intense. What makes GD&T so valuable is that it keeps parts working properly even when temperatures change or mechanical forces kick in. According to some industry research from Components By Design back in 2025, this attention to detail actually cuts down on breakdowns in car transmissions by about a fifth compared to older manufacturing methods that didn't use these specifications as rigorously.

How Precision Tolerances in CNC Machining Impact Performance

How precise something is really matters for how long parts last and how well they work overall. Take turbine blades for instance those with surface flatness under about 5 microns can boost fuel efficiency around 8% in jet engines. On the flip side when robotic joints aren't manufactured to tight specs, alignment problems often pop up. These issues typically exceed 0.1 degrees of error which leads to motors burning out way too soon. Modern high speed CNC equipment now comes equipped with real time path correction features. These advanced systems manage to keep within roughly plus or minus 0.0002 inches of accuracy even when handling complicated five axis machining tasks.

Balancing Tolerance Selection to Reduce Cost and Lead Time

Optimal tolerance selection requires prioritizing critical features while relaxing non-functional dimensions. A study showed specifying IT7-grade tolerances (0.0021") instead of IT5 (0.0007") for non-load-bearing housing components cut machining costs by 41% without sacrificing performance. Manufacturers using tiered tolerance systems report 18% faster project completion rates compared to uniform tolerance approaches.

Case Study: Achieving Tight Tolerances in Aerospace Components

A leading aerospace manufacturer reduced engine mount failures by 57% after implementing ±0.0005" parallelism tolerances on mounting surfaces. Using ceramic-coated carbide tools and in-process laser scanning, they achieved 99.94% compliance across 12,000 units while maintaining a 23-day production cycle—demonstrating that strategic tolerance management enables reliability without sacrificing scalability.

Surface Finish, Material Selection, and Functional Performance

Evaluating Surface Finish and Roughness for Functional Requirements

The surface finish of a CNC part has a major effect on how it performs in real world applications. For parts that experience heavy wear, typical roughness measurements (Ra) fall between 0.4 and 1.6 micrometers. When surfaces are really smooth, below 0.8 micrometers Ra, there's less friction in moving parts which matters a lot for things like pistons or gears. On the flip side, some level of controlled roughness around 1.2 to 3.2 micrometers actually helps when bonding materials together, something critical in aircraft manufacturing where adhesives need to stick properly. Most engineers have to work within the guidelines set by ISO 1302 standards but also consider what the part will actually face in service. Sometimes this means making tradeoffs between standard requirements and practical needs such as preventing leaks in hydraulic systems or ensuring parts won't corrode over time in harsh environments.

Common Post-Machining Treatments to Enhance Surface Quality and Finish of CNC Parts

Anodizing aluminum parts increases corrosion resistance by 40% compared to untreated surfaces, while electropolishing stainless steel eliminates micro-burrs that compromise medical device sterility. Shot peening improves fatigue life in titanium components by up to 25%, and powder coating provides UV stability for automotive parts exposed to harsh weather.

Matching Material Selection for CNC Machining with Application Demands

Aluminum 6061 dominates prototyping due to its machinability, while 316L stainless steel serves most marine applications for chloride resistance. Recent advancements in carbon-fiber-reinforced polymers now support lightweight robotics arms previously limited to metallic alloys.

Comparing Aluminum, Steel, Titanium, and Engineering Plastics in CNC Parts

| Material | Strength-to-Weight Ratio | Corrosion Resistance | Cost per kg |

|---|---|---|---|

| Aluminum 7075 | 140 MPa·m³/kg | Moderate | $8-12 |

| Titanium Grade 5 | 260 MPa·m³/kg | Excellent | $50-80 |

| PEEK Plastic | 90 MPa·m³/kg | Extreme | $100-150 |

How Mechanical Properties Influence Part Durability and Performance

Yield strength dictates load capacity in structural components, while thermal conductivity (3-150 W/m·K across metals) determines heat dissipation in electronics housings. Fatigue limits in steel alloys (200-800 MPa) enable 10+ cycles in powertrain components, and creep resistance in nickel superalloys prevents deformation in jet engine parts operating above 650°C.

Repeatability and Consistency in High-Volume CNC Manufacturing

Ensuring Repeatability and Consistency in Manufacturing Across Production Runs

CNC machining really shines when it comes to making thousands of parts that all look exactly the same. The machines follow programmed paths and run G-code instructions without letting human mistakes creep in. This matters a lot in places like car factories and airplane component manufacturing, where getting even one part wrong can cause big problems down the line. Parts need to fit together perfectly, so manufacturers rely on these machines to produce consistent results across entire production runs. Some modern CNC setups actually keep track of past performance data. When something starts going off track, the system can spot issues before they become major problems, which helps maintain quality standards throughout long manufacturing periods.

Process Controls That Minimize Variation in High-Volume CNC Parts Production

Three key controls optimize consistency:

- Machine calibration using laser alignment and ballbar testing to maintain ±0.001" accuracy

- Real-time monitoring systems that track spindle load, temperature, and vibration

- Adaptive toolpaths that automatically adjust for tool wear

These measures reduce dimensional variation by 83% compared to manual processes (Precision Manufacturing Journal, 2024), enabling cost-effective mass production of CNC parts without quality compromises.

Data Point: 99.8% Consistency Rate Achieved in Automotive Component Batches

A 2024 study of 1.2 million automotive transmission components showed CNC-machined parts achieved a 99.8% consistency rate in critical bore diameters (±0.0005") and surface finish (Ra â—‡ 0.8 μm). This reliability directly correlates with a 40% reduction in assembly-line rejections, demonstrating how precision machining impacts end-product performance.

Controversy Analysis: Automation vs. Manual Oversight in Maintaining Consistency

Full automation does reduce variability quite a bit, but many people still point out that it has trouble dealing with those complicated shapes where human eyes just work better. The latest stuff coming out of machine learning powered CNC systems though? Pretty impressive actually. These new systems can spot defects at about 97% of what human inspectors do, and they do it three times quicker too according to Manufacturing Technology Review from last year. What we're seeing more and more in important manufacturing sectors is this mix approach where machines take care of the everyday checking tasks while experienced workers focus on the really tricky parts that need their expertise. Seems like finding that sweet spot between tech and human touch is becoming standard practice these days.

Design for Manufacturability to Optimize CNC Part Quality

Avoiding Design Pitfalls Like Thin Walls and Deep Cavities in CNC Machining

Parts with thin walls measuring less than 0.8mm in aluminum or around 1.5mm in steel tend to bend or warp when subjected to machining forces, which can really mess up the overall strength of the component. When dealing with deep cavities where the depth is more than four times the diameter, there's a much higher chance of tools bending out of shape during cutting operations. This means manufacturers have to invest in special tools just to handle these tricky geometries, and those specialty tools typically cost somewhere between 18% and 25% more than standard equipment. Most experienced engineers know that following good old DFM guidelines from the start of the design process saves headaches later on. Getting the basic shapes right early prevents all sorts of manufacturing problems down the road.

Optimizing Complex Geometries Without Compromising Part Quality and Precision

Complex designs require balancing functionality with machinability. Standardizing fillet radii (â—Ž1mm for most metals) and limiting tight tolerances (±0.05mm) to critical features reduces machining complexity. For example, aerospace actuators achieve ±0.025mm accuracy by simplifying internal channel geometries while maintaining fluid dynamics performance.

How Design Choices Affect Tool Access and Machining Efficiency

Internal sharp corners force smaller end mills, increasing cycle times by 25-40%. Designs with 5mm+ tool clearance around features enable full-depth cuts, reducing vibration and improving surface finish (Ra ◇1.6μm). Strategic chamfer placements decrease tool changes by 30% in automotive component batches, directly lowering per-part costs.

Quality Assurance and Advanced Inspection Protocols for CNC Parts

Implementing Quality Control and Inspection Protocols from Prototype to Production

Quality control starts with what's called First Article Inspection or FAI when checking if prototypes match the original design specs. Most companies then do regular checks throughout different stages of production where things could go wrong. Big name manufacturers stick to strict standards like ISO 9001 and AS9100 certifications so they can track everything from the raw materials all the way through machining until the product gets validated for release. Take the auto industry for instance they require something called Statistical Process Control or SPC to keep parts within really tight tolerances sometimes as small as plus or minus 0.005 inches. This matters a lot in fields where even tiny measurements make a huge difference in performance and safety.

Using CMM, Profilometer, and Digitizing Scanners for Precision Inspection

CMMs can check those complicated shapes down to under 0.0002 inches repeatable accuracy, whereas laser profilometers get surface roughness measurements right down to about 1 microinch precision. The digitizing scanners out there today are pretty amazing too they grab full 3D profiles of those irregular surfaces and let engineers compare them directly with their CAD designs in no time flat. According to some research from NIST back in 2022, switching from old school measuring techniques to these modern systems cuts down on measurement mistakes by around three fifths. For industries where even tiny deviations matter a lot like aerospace manufacturing and defense contracting this kind of accuracy isn't just nice to have it's absolutely essential for meeting those tight tolerance requirements.

In-Process Inspections and Real-Time Adjustments in CNC Workflows

Automated probing systems detect tool wear or fixturing shifts during machining, triggering immediate offsets to maintain positional accuracy. Real-time monitoring of parameters like spindle load and coolant flow reduces scrap rates by 38% in high-volume production (SME 2024).

Specifying Critical Dimensions for Quality Inspection in High-Stakes Industries

Aerospace components require ±0.0004" bore concentricity checks, while medical implants demand surface finish below 16 µin Ra. Underspecifying critical dimensions is responsible for 92% of CNC part failures, underscoring the need for risk-based inspection planning.

Trend Analysis: AI-Driven Inspection Systems Enhancing Defect Detection

Machine learning algorithms now process CMM data to predict tool degradation 15% earlier than traditional methods, reducing unplanned downtime. Vision systems paired with AI achieve 99.96% defect recognition accuracy in threaded fasteners (IEEE 2023), setting new benchmarks for zero-defect manufacturing.

FAQ

What is dimensional accuracy in CNC machining?

Dimensional accuracy refers to how precisely a CNC-machined part conforms to the intended design specifications or dimensions given on a technical drawing.

Why is Geometric Dimensioning and Tolerance (GD&T) important?

GD&T provides a standardized way to communicate how parts fit together and function, even under various conditions, thus ensuring the correct assembly and performance of parts.

How does surface finish affect CNC part performance?

Surface finish impacts how a part interacts with other surfaces. Smoothness can reduce friction for moving parts, while controlled roughness can be beneficial for adhesive bonding.

How can CNC machining reduce production variations?

CNC machines use programmed paths and adaptive controls, such as real-time monitoring and toolpath adjustments, to minimize variations and improve consistency in high-volume production.

Table of Contents

-

Precision and Dimensional Accuracy in CNC Machined Parts

- Understanding Tolerances and Dimensional Accuracy in CNC Parts

- The Role of Geometric Dimensioning and Tolerance (GD&T) in Part Functionality

- How Precision Tolerances in CNC Machining Impact Performance

- Balancing Tolerance Selection to Reduce Cost and Lead Time

- Case Study: Achieving Tight Tolerances in Aerospace Components

-

Surface Finish, Material Selection, and Functional Performance

- Evaluating Surface Finish and Roughness for Functional Requirements

- Common Post-Machining Treatments to Enhance Surface Quality and Finish of CNC Parts

- Matching Material Selection for CNC Machining with Application Demands

- Comparing Aluminum, Steel, Titanium, and Engineering Plastics in CNC Parts

- How Mechanical Properties Influence Part Durability and Performance

-

Repeatability and Consistency in High-Volume CNC Manufacturing

- Ensuring Repeatability and Consistency in Manufacturing Across Production Runs

- Process Controls That Minimize Variation in High-Volume CNC Parts Production

- Data Point: 99.8% Consistency Rate Achieved in Automotive Component Batches

- Controversy Analysis: Automation vs. Manual Oversight in Maintaining Consistency

- Design for Manufacturability to Optimize CNC Part Quality

-

Quality Assurance and Advanced Inspection Protocols for CNC Parts

- Implementing Quality Control and Inspection Protocols from Prototype to Production

- Using CMM, Profilometer, and Digitizing Scanners for Precision Inspection

- In-Process Inspections and Real-Time Adjustments in CNC Workflows

- Specifying Critical Dimensions for Quality Inspection in High-Stakes Industries

- Trend Analysis: AI-Driven Inspection Systems Enhancing Defect Detection

- FAQ