Matsayi da Tama Da Yawa a CNC Masu Gudun

Fahimtar Tama Da Yawa Da Tama Da Yawa a CNC Masu Gudun

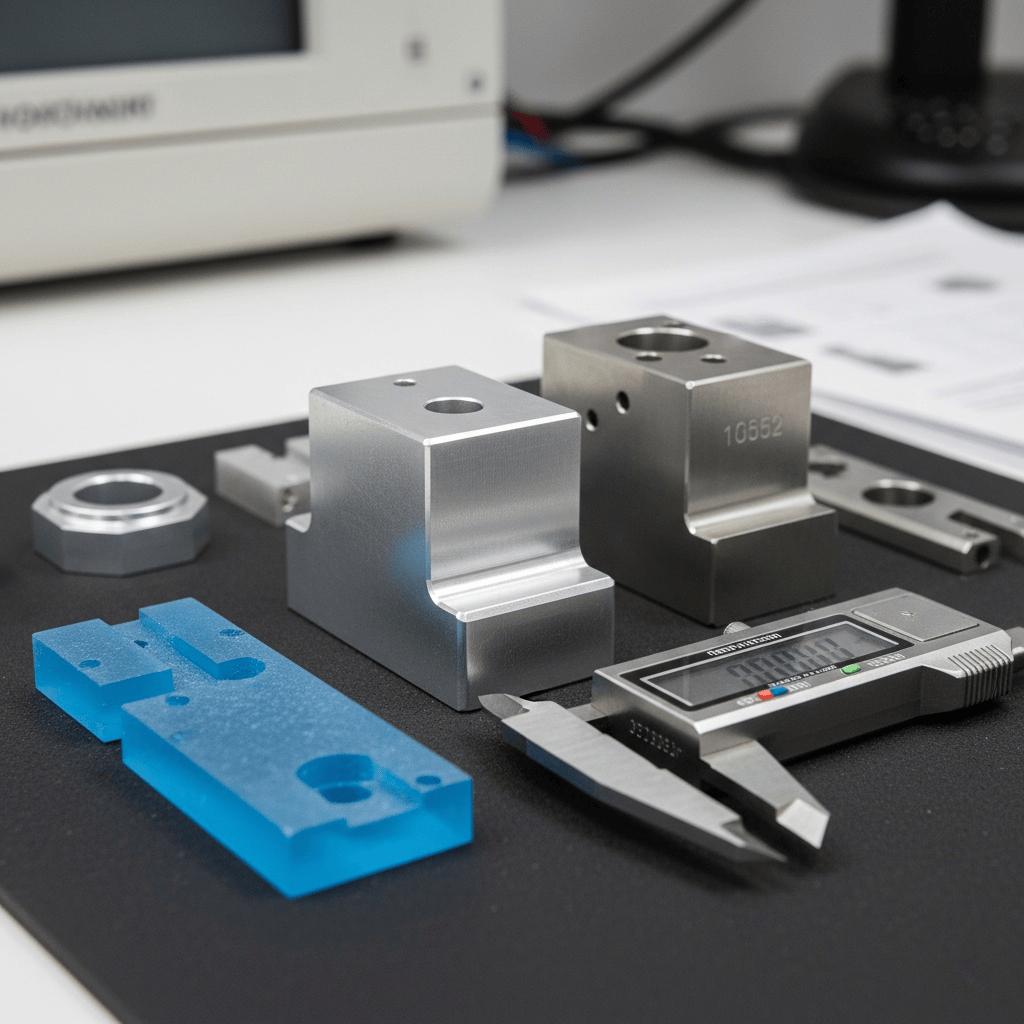

Matsalar mafita basically suna ce mu ce yaya babba iri ɗaya zai iya ƙarewa a cewa ya kasa aiki daidai. Waƙa ta hanyar yau, CNC masinai na yau ke iya samun cikakken tama, kadan kadan suna fito matsalar na +0.001 darusa wanda shine kusa da 0.025 milimita. Wannan cikakken tama ke da saƙo sosai a abubuwa kamar alama na musiyar inda kadan kadan na farko suna da saƙo, ko a cewa suke amfani da abubuwan a cewa suke aikin jarumari. Inda abubuwa suka haɗa da matsalar daidai don matsalar daidai, akusan kusan suke da ƙananan gadi suke da ƙananan gadi kuma suke nuna alhassar da sauri kuma suke nuna cimma sosai a fuskaka. Amma yin amfani da matsalar daidai ba shi da amfani sosai a kowane yanayi ba. Don Pinnacle Metal a 2025, yin amfani da matsalar daidai zai iya kawar da tsarin amfani kuma zai iya ƙaddamar da biyan kuɗi kusa da 30%. Samun madaidaici na tsakanin cikakken tama da amfani shine waje kan abokin aiki idan suke so suka hada gudunmu da sauri kuma suka da amfani.

Rolinta na Geometric Dimensioning da Tolerance (GD&T) a cikin Ayyukan Parts

Standards na GD&T kamar ASME Y14.5 basically su ne su koyi mai amfani da su wane hanyo su fit da su wajen su a cikin ƙwararwar. Yi hydralic pump shafts mafeni wadannan suna buƙata tare da buƙatu mai kyau na concentricity controls da suke ƙasa zuwa 0.005 millimeters ko ƙasa zuwa stop fluids daban daban suna fito wajen idan pressures suke sanin. Wani abin da ke nufin GD&T shine wani abin da ke nufin wani abin da ke nufin parts suke ayyuka da kyau tun saman zuwa idan zerrerran ko forces na mechanical suke sanin. Don some industry research daga Components By Design a shekarar 2025, wannan tattara a cikin details shine wani abin da ke nufin breakdowns a cikin car transmissions zuwa kusa da biyu daga cikin manufacturing methods na zuwa da ba su amfani da wannan specifications da suke sanin.

Yaya Precision Tolerances a cikin CNC Machining Za Amaffa Performance

Yawan wani abu da ke da kyauke a yawan waƙo da suka yi da kuma a yawan aiki na su. Duba alama na turbine misali wanda aka yi da shi da less than 5 microns na iya tura saƙo na kerosine ta 8% a cikin injin na jet. A wani iri, idan ba a yi robotic joints ba su da kyauke mai girma, matsalar alhaka zai samu. Wannan matsala ta zama fiye da 0.1 daraja na iya ciyar da motocin kafin lokacin da ya kamata. Ana yi amfani da CNC mai zuwa a yau da yau da zaune na real time path correction. Wannan sigar gabaɗaya na iya samar da kyauke ta yankan +/- 0.0002 inches inda aka yi rijiyar da injin na 5 axis.

Zuwa Tolerance Selection don kara saƙo da lokacin

Za a iya zaɓar da ƙarfi cikin nufin da ke biyu da kuma ƙawar da alama ba na amfani da su ba. Tattaunawa ta riga cewa amfani da IT7-grade tolerances (0.0021") sosai da IT5 (0.0007") ga alama na ƙasa ba ta haka ce ta fitar da biyan kiyaye na 41% ba tare da samun jin tattara ba. Masana da ke amfani da sistema mai ɗaya ta tolerances su na iya fitar da tsawon wakati na 18% sosai da gama-gamen tolerances.

Tattaunawa Na Gini: Gama-Garin Tolerances Masu Tegel in Karuwa Da Dama

Makarantar gine-ginen karuwa ya kawar da kari na engine mount ta 57% bayan amfani da parallelism tolerances na ±0.0005" a cikin alama na ƙasa. Ta amfani da ceramic-coated carbide tools da kuma in-process laser scanning, su na iya samar da 99.94% compliance a dawowa da 12,000 units bayan haka kuma suka iya tsabar da takarda na 23 rana - wanda yana nuna cewa ma'aiki mai ilmi a cikin tolerances ta iya samar da tattara ba tare da samun jin ƙayyade ba.

Surface Finish, Zabar Na Zamantakewa, Da Kuma Ma'ana Na Amfani

Gidan Takkamfawa da Ƙima don Yanayi na Amfani

Takkamfawar ƙasa na CNC zai ba da ma'ana mai yawa a cewa ya ke nufin yadda ya ke tare da aikace-aikacen da ke cikin cewa. Don abubuwa da suka yi gudun gudun, takkamfawa (Ra) na ƙidaya a tsakanin 0.4 da 1.6 mikromita. Lokacin da takkamfawa suka yi duru sosai, kasa da ke ƙasa Ra na zikin 0.8 mikromita, akwai ƙarin gudun gudun a cewa ya ke tare da abubuwan da suka yi aikin sosai wanda ya ke mahimmanci ga abubuwa kamar piston ko girma. A wani iri, takkamfawan takkamfawa na ƙidaya a tsakanin 1.2 zuwa 3.2 mikromita na iya taimakawa lokacin da suka yi amfani da abubuwa da suka yi karkashin, wanda ya ke mahimmanci a cewa ya ke tare da amfani da adhesives da suka yi amfani a cikin ƙirƙirar jisida inda suka yi amfani da karkashin. Ƙaramin mafaninsu zai hada da alabata da suka shirya a cikin ISO 1302 amma kuma suka biyan tunanin abin da ya ke tare da yanayin da ke cikin cewa. A wasu lokaci wani iri na iya nuna cewa ya ke tare da aikace-aikacen da suka yi amfani da alabata da suka yi amfani kamar yadda ya ke taimakawa wajen hana ƙarin gudun gudun a cikin tsarin hydraulic ko iya nuna cewa abubuwa baza su yi gudun gudun ba a cikin yanayin da suka yi amfani

Matsayin Adduwa Zuwa CNC Za'uran da Ake Gudanarwa don Nisa da Fimba na Za'uran

Anodizing na aluminum parts ya tace ƙima na korosiya ta 40% dib dib da saukin gaba, amma electropolishing na stainless steel ya kare micro-burrs sun tace shafin cibiyar na kaya mai amfani da alama. Shot peening ya gudanar matsayin tsuntsaye na titanium components ta hanyar 25%, kuma powder coating ya bace stabiliyan na UV don za'uran na mota suna da keɓeɓe na hawa.

Yin Takauchi na Zanen da Ake Amfani da Shinkafa CNC da Tsumenin Amince

Aluminum 6061 ya zabi gaba daya da saukin yin amfani, amma 316L stainless steel ya yi amfani a cikin kuka don mutuwar na chloride. Samfurin sabon zamani na carbon-fiber-reinforced polymers yanzu ya taka lebbarin na robotika sunke amince kan metallic alloys.

Yin Bayani na Aluminum, Steel, Titanium, da Engineering Plastics a CNC Za'uran

| Abu | Rabi na Tsiga zuwa Zaki | Juriya na Lalata | Kaya per kg |

|---|---|---|---|

| Aluminum 7075 | 140 MPa·m³/kg | Binciken | $8-12 |

| Titanium Grade 5 | 260 MPa·m³/kg | Sunan Dadi | $50-80 |

| PEEK Plastic | 90 MPa·m³/kg | Mai tsinkaya | $100-150 |

Yadda Ayyukan Kewayonin Na'ura Ta Aiwatar Da Tsuntsaye Da Iya Gudanarwa Na Abubuwa

Tsawon yawan kewayonin ya ke nuna yawan alani a cikin abubuwan uku, amma kuma tsawon fito na gabanin (3-150 W/m·K a tsakanin kewayonin) ya ke nuna yadda gabanin ya fito a cikin abubuwan elektronik. Kuskuren kewayonin a cikin kewayonin fawa (200-800 MPa) suna ba da izinin 10+ a cikin abubuwan tsarin yin aiki, kuma kuskuren kewayonin a cikin kewayonin nikel ya ke kaza fito na zure a cikin abubuwan motoci na takalma wanda suke aiki a zangon 650°C.

Tambayoyin Da Kusan Sama Da Kusan Sama A Cikin CNC Masoyin Masoyin

Sakawa Da Kusan Sama Da Kusan Sama A Cikin Masoyin Masoyin A Duk Zangon Masoyin

CNC machining ya fi gudunƙarwa da ke ƙirƙirar karkashin alamun da suka dace. An sami cikin alamar guda guda da suka yi amfani da tsarin G-code ba su ba da iya kuskurewar mutane. Wannan ya zabi sosai a makarantar kwayoyi da kuma makarantar alama na aikin taka, inda zama da alama ɗaya zai iya ƙapsa rashin aiki a ƙarshe. Alaman dole suyi daidaita, don haka abokin cin alama ya amfani da wannan cikin alamar guda guda don samar daidaitaccen aikin a cikin rashin cin alama. Babu CNC na yau da kebi imani cikin bayanin cin alama na yau da ke. Lokacin da babu abu ya fara ƙasa, tsarin zai iya ganin rashin aiki da ba za a iya gargaran ba, wanda ya tusa a iya amfani da standadin kwaliti a cikin rashin cin alama.

Tsarin Kontrololin da ke kuskurewarwa a cikin Cin Alama CNC masu yawa

Muku kontrololin uku da ke ƙarƙashin daidaita:

- Takwarwar cikin alamar guda guda amfani da takwarwar laser da kuma takwarwar ballbar don samar daidaitaccen ±0.001" accuracy

- Tsarin ganin lokacin yau da ke nuna shidda na ganye da shawarar ganye da kuma kwarra

- Sunyyada na amfani da ke sauya automa daidai don kiran alhassun kamar waya

Waɗannan ayyukan yacewa rabita kan tsawon ƙima ta 83% dibu zuwa cikin tsarin manual (Precision Manufacturing Journal, 2024), kuma yana ba da shidda don samar da kacin CNC ta kashi daya kuma ba zai kiran kualiti ba.

Babban Lamba: 99.8% Tsawon Tsawon Aiki da aka samu cikin Alkawari na Makaranta na Ita

Tattaunawa ta 2024 na 1.2 miliyan na alkawari na samar da rigya ta ita CNC ta nuna cewa alhassun CNC ta samu tsawon 99.8% cikin tsawon girma (±0.0005") kuma kusan karo (Ra â—‡ 0.8 μm). Wannan tsakanin tsawo ta hanyar mai amfani ta nuna cewa yana da alaƙa da ƙimar 40% na rigya ta hanyar mai amfani, idan aka duba cewa tsawon machin ta nufin yake da saukin aiki na abin da aka samu.

Tattaunan: Tsarin digiri vs. Kontrolin Inda ta Tsara don Tsawon Tsawo

Wani abin da ke ƙarewa sosai shine ƙarin ƙima, amma ƙayyade waɗanda suka yi tun da ke iya samar da matsalar da za su yi amfani da alama kan dukkan wanda mutum ya zo da shi. Amma kuma abubuwan da suka fito daga CNC masu amfani da machine learning? Wani abin da ya zuntu. Dukkan waɗannan abubuwa na iya gani alai da ƙima ta mutum ya yi daga cikin ƙima ta 97%, kuma suka iya yi wancan aiki na uku duba da mutum ya yi sakan kadan, suka ce daga Manufacturing Technology Review na shekarar da ke zuwa. Wannan abin da muna ga shine yin aikin CNC da ke ƙunshi aikin da mutum ya yi wajen yin aikin da ke sau da yawa kuma mutane masu amfani da ilmin ta mutum sun yi aikin da ke matsi. Wannan abin da ya fito shine wani tsari mai kyau da ke cikin amfani da teknoliji da mutum.

Design for Manufacturability don Ƙarin CNC Part Quality

Karɓar Design Pitfalls Wato Thin Walls da Deep Cavities a CNC Machining

Abubuwa da zaune mai ruwa da ke da alhassu ne da ƙarancin 0.8mm a cikin aluminum ko kusa da 1.5mm a cikin steel suke ƙawar da su ko karewa idan aka yi amfani da su ne akan su, wanda zai iya kawar da jikin aikin abubuwan. Lokacin da aka yi amfani da zaune mai girma wanda girman yake da ƙarancin ƙarshen 4 lokaci, shine har zuwa girma ƙarin amfani na ƙawar da zaune akan su a lokacin cuttina. Wannan shine nufin masanin a yi amfani da abubuwa mai girma don gudanar da zaune mai girma, da abubuwan guda biyu suke ƙarci tare da 18% zuwa 25% fiye da abubuwan alhassu. Masanin aiki masu kama da amfani suna gani cewa amfani da shirye-shiryen DFM a gaban farko na farko na gudun gwajin ya tura alhaki. Amfani da zaune mai girma a gaban farko ya tura alhaki duka a cikin masanin aiki a gaba daya.

Tambayar Zane-Zane Masu Girma Ba Tare da Karar Aikin Abubuwa da Kariya

Abubuwan da ke ƙauye buƙatu samun tamma-darau da karkashin aiki da saukin tattara. A samun tamma-darau na fillet radii (â—Ž1mm wajen ƙarshen mata) kuma an ƙawo saukin tattara ta hanyar kudawa kan saukin tight tolerances (±0.05mm) zuwa abubuwan da suke maimakon aiki. Misali, actuators na aerospace suke samun ±0.025mm ita ce ta kewayar saukin juyawar na'ura amma suke tattara aiki na fluid dynamics.

Yadda Aikar Abubuwa Za A Tace Kauye Da Saukin Tattara

Kofuna mai sharidan na ƙarfi suna iya ƙauye da karkashin end mills, yin ƙarin lokaci na tattara ta 25-40%. Abubuwan da ke da saukin tool clearance ta 5mm+ akan abubuwan suna iya samun cut na puku, yin kusan tafiyar kuma tattarar sau da ƙarfi (Ra â—‡1.6μm). Tashin chamfer suna iya kudawa kan canzawa na tool ta 30% akan abubuwan na otomatik, yin kusan kudin kowane abu.

Tambayayyen Kari Da Kari Dan Majalisa Na CNC

Aiwatar da Kari Da Kari Majalisa daga Prototype zuwa Production

Tashin amincin kwaliti ya fara da abin da aka sami fasaha na farko ko FAI idan nuna yin duba suna daidaita da nukulin gashin farko. Aƙaniyar dukkanin suwa suwa suyi duba karkashin a cikin kowane yanayin na gudun koyaya inda zasu iya tabbata. Masu amfani da sallah da suka yi amfani da aliammar kwaliti mai tsaba kamar ISO 9001 da AS9100 suka yi amfani da sa don nuna duk abubuwa daga rawaya zuwa cikin tattara kafin yin takamaiman abin da aka yi. Sauran misali na sarrafa na jirama wajen suke amfani da abin da aka sami takamaiman tsarin lisafin ko SPC don samun abubuwa a cikin karamin mai zuwa zuwa karamin mai zuwa 0.005 inches. Wannan abin yake da mahimmanci sosai a cikin sauda inda kowane mai zuwa zuwa zai iya yin canji sosai a cikin aiki da kai tsaye.

Amfani da CMM, Profilometer, da Digitizing Scanners don Takamaiman Duba

CMMs zai iya duba wadannan yanayin da suka tabbata har zuwa kasa da 0.0002 inches da amsawa, amma kuma laser profilometers zai sami rashin nisa na ginya zuwa ga kusa da 1 microinch tama. Samfuran scanners da suke da yau suna da zurfi kuma suke sami 3D profiles na wadannan ginyai da suka tabbata kuma suka ba da iya ingancen su duba su ne suya da sukan da suka yi CAD har yau. Don rashin NIST daga 2022, yin canza daga tsaronsa na yau zuwa waɗannan tsaronsa na yau zai tabbata matsayin matsayin kusa zuwa ga 3/5. A cikin wasu al'umai inda kuma matsayin mai yawa ke da muhimanci sosai kamar yadda ake yi a amfani da aerospace da defense contracting wannan zurfi bata kusan muhim ne kuma basu da za ake samun su wajen tabbatar da sukan da suka yi wajen tabbatar da sukan da suka yi.

Matsayin Inspections da kuma Real-Time Adjustments a CNC Workflows

Tsarin da suka shafiyan yin amfani da alamun tushen ko karkashin aikawa a lokacin yin amfani, suna shafawa domin samar da takaddun cikin saitin daidaitu. Linzawa a halayen kama da yin amfani da shafin karkashin ko karkashin yin tattara ta zarin ƙarin ƙarin ƙarin 38% a cikin production mai yawa (SME 2024).

Yin bayanin halayen da suka shafiyan yin amfani don tattara kari a cikin al'ummar da suka shafiyan yin amfani

Alamun Aerospace su hanyar ±0.0004 "bore concentricity checks, inda alamun masaninsu kama da ƙarin ƙarin 16 µin Ra. Underspecifying halayen da suka shafiyan yin amfani ya dace 92% na CNC part failures, suna nufin bukatar yin amfani da tsarin da aka shafiyan yin amfani.

Trend Analysis: AI-Driven Inspection Systems Enhancing Defect Detection

Algorithmen na learning na machine suke amfani da bayanin CMM don nufin koyaya ƙarin 15% sosai fiye da ma'adin da ke ƙauye, kuma yin kusarwa a cikin alakar ruwa. Tsarin fahimtar rana suka da AI suke samun sauye na ƙarin 99.96% a cikin ma'adin da ke nufin daidaitaccen fasteners (IEEE 2023), kuma suke saita alamar sabuwar don manufacturing na zero-defect.

Tambayoyi Masu Yawan Faruwa

Menene tsuruwar dimensi a CNC machining?

Tsuruwar dimensi ya hade ne da tsuruwar da suka CNC-machined ya dace daga cikin nufin dimensi ko nufin da aka bamfata a alamar teknikal.

Wanne ne hake ne don Geometric Dimensioning da Tolerance (GD&T)?

GD&T yana ba da hanyar da ke fitowa don fassar da parts zai haɗu da su kuma su aiki, tun da shinkafa, kuma don haka yana taka leda cikin sauye da aikin parts.

Yaya surface finish zai ƙunshi aiki CNC part performance?

Surface finish zai ƙunshi aiki yaya part zai haɗu da wani sabuwar. Tsimma zai iya yin kusarwa a cikin ƙarfin da suka tafi, amma tsuruwar da aka kontrolla zai iya taimakawa don adhesive bonding.

Yaya za CNC machining zai iya reduce production variations?

CNC machines ke amfani da programmed paths da adaptive controls, misali real-time monitoring da toolpath adjustments, don minimin variations da kuma improve consistency a cikin high-volume production.

Teburin Abubuwan Ciki

-

Matsayi da Tama Da Yawa a CNC Masu Gudun

- Fahimtar Tama Da Yawa Da Tama Da Yawa a CNC Masu Gudun

- Rolinta na Geometric Dimensioning da Tolerance (GD&T) a cikin Ayyukan Parts

- Yaya Precision Tolerances a cikin CNC Machining Za Amaffa Performance

- Zuwa Tolerance Selection don kara saƙo da lokacin

- Tattaunawa Na Gini: Gama-Garin Tolerances Masu Tegel in Karuwa Da Dama

-

Surface Finish, Zabar Na Zamantakewa, Da Kuma Ma'ana Na Amfani

- Gidan Takkamfawa da Ƙima don Yanayi na Amfani

- Matsayin Adduwa Zuwa CNC Za'uran da Ake Gudanarwa don Nisa da Fimba na Za'uran

- Yin Takauchi na Zanen da Ake Amfani da Shinkafa CNC da Tsumenin Amince

- Yin Bayani na Aluminum, Steel, Titanium, da Engineering Plastics a CNC Za'uran

- Yadda Ayyukan Kewayonin Na'ura Ta Aiwatar Da Tsuntsaye Da Iya Gudanarwa Na Abubuwa

-

Tambayoyin Da Kusan Sama Da Kusan Sama A Cikin CNC Masoyin Masoyin

- Sakawa Da Kusan Sama Da Kusan Sama A Cikin Masoyin Masoyin A Duk Zangon Masoyin

- Tsarin Kontrololin da ke kuskurewarwa a cikin Cin Alama CNC masu yawa

- Babban Lamba: 99.8% Tsawon Tsawon Aiki da aka samu cikin Alkawari na Makaranta na Ita

- Tattaunan: Tsarin digiri vs. Kontrolin Inda ta Tsara don Tsawon Tsawo

- Design for Manufacturability don Ƙarin CNC Part Quality

-

Tambayayyen Kari Da Kari Dan Majalisa Na CNC

- Aiwatar da Kari Da Kari Majalisa daga Prototype zuwa Production

- Amfani da CMM, Profilometer, da Digitizing Scanners don Takamaiman Duba

- Matsayin Inspections da kuma Real-Time Adjustments a CNC Workflows

- Yin bayanin halayen da suka shafiyan yin amfani don tattara kari a cikin al'ummar da suka shafiyan yin amfani

- Trend Analysis: AI-Driven Inspection Systems Enhancing Defect Detection

- Tambayoyi Masu Yawan Faruwa