Why Aluminum Is a Top Choice for CNC Machining

Aluminum is king when it comes to CNC machining because of how strong it is relative to its weight and the fact that it doesn't corrode easily. More than half of all parts made through CNC processes in both aerospace and car manufacturing rely on different types of aluminum alloys. These materials cut down on weight significantly, somewhere between 40 to 60 percent lighter than steel equivalents, yet still hold up structurally just fine. What makes aluminum so great for these applications? Well, there's this natural oxide coating that forms on the surface, acting as a built-in shield against rust. Components made from aluminum last much longer, especially important in places where moisture is always present, like near coastal areas or inside vehicles exposed to road salt during winter months.

Common Aluminum Alloys Used in CNC Parts: 6061 vs 7075

| Property | 6061 Aluminum | 7075 Aluminum |

|---|---|---|

| Tensile Strength | 40,000 psi | 83,000 psi |

| Density | 2.7 g/cm³ | 2.8 g/cm³ |

| Primary Applications | Automotive frames | Aerospace fittings |

| Machinability Rating | Excellent (95/100) | Good (75/100) |

6061 remains the go-to alloy for prototypes and general-purpose parts due to its balance of formability and cost. In contrast, 7075 excels in high-stress applications like aircraft wing spars, where its zinc-enhanced composition delivers twice the fatigue resistance of 6061.

Thermal and Electrical Conductivity Benefits

Aluminum’s thermal conductivity (120–210 W/m·K) makes it ideal for heat sinks in electronics, dissipating 30% faster than stainless steel. Its electrical conductivity (35.5×10⁶ S/m) also positions it as a preferred material for busbars and connector housings, minimizing energy loss in power transmission systems.

Case Study: Aerospace Applications

A 2023 redesign of satellite mounting brackets using 6061-T6 aluminum reduced total assembly weight by 22%, enabling longer mission durations. Post-machining anodizing improved surface hardness by 300%, meeting aerospace radiation shielding requirements.

Trend: Sustainable CNC Manufacturing with Recycled Aluminum

The adoption of recycled aluminum alloys in CNC parts has surged by 52% since 2020. Modern smelting techniques now recover 95% of post-production scraps without compromising machinability, aligning with ISO 14040 lifecycle standards while cutting material costs by 18–25%.

Steel and Stainless Steel for Durable CNC Parts

Steel alloys dominate industrial CNC applications requiring extreme durability, with over 60% of heavy machinery components using steel-based materials. Manufacturers prioritize steel for its unmatched structural integrity in high-stress environments.

Mechanical Strength of Steel CNC Parts in Industrial Applications

Steel components produced through CNC machining can handle some serious tension, reaching as high as 2000 MPa in hydraulic systems and various types of press machines. When it comes to high carbon steels such as grade 4140, these materials actually hold about 120 percent more weight compared to their aluminum counterparts. That's why we see them so often in places where things get really rough on equipment joints in mines, inside those tough automotive transmissions, and even in the gears of heavy construction machinery. For many manufacturers looking at costs though, there's still something to be said for good old 1045 carbon steel. It offers around 580 MPa of yield strength which means parts made from it last longer while still being relatively easy to machine. This makes it pretty popular among companies producing fasteners who need that sweet spot between what works well and what doesn't break the bank.

Corrosion Resistance of Stainless Steel CNC Components

Stainless steel CNC parts reduce equipment replacement costs by 40% in corrosive environments compared to untreated carbon steel. The chromium oxide layer in grades like 304 and 316 provides:

| Grade | Saltwater Resistance | Acid Resistance (pH <3) | Max Operating Temp |

|---|---|---|---|

| 304 | Moderate | Low | 870°C |

| 316 | High | Moderate | 925°C |

Food processing and marine industries use 316 stainless steel for pump components exposed to chlorides and organic acids.

Comparison: 304 vs 316 Stainless Steel in CNC Machining

While both grades offer superior corrosion resistance, 316 stainless steel contains 2–3% molybdenum for enhanced performance in offshore oil rig valve bodies, pharmaceutical mixing blades, and chemical processing reactor liners. 304 remains preferred for budget-conscious projects without extreme environmental demands, accounting for 65% of commercial kitchen CNC components.

Strategy: When to Choose Steel Over Aluminum for CNC Parts

Steel CNC parts should be chosen for components that operate at temperatures over 500 degrees Celsius, need tensile strength above 400 MPa, or deal with abrasive wear during mineral processing operations. Aluminum makes sense mainly when reducing weight is more important than maintaining strength properties since steel stands up to repeated stress much better, offering around three times the fatigue resistance in these kinds of applications. According to various industry reports, roughly 72 percent of manufacturers still go with steel for their load bearing CNC components on vertical machining centers, probably because nobody wants to risk failure just to save a few pounds.

Why Titanium Is Used for Critical CNC Parts in Aerospace and Medical Devices

Ti-6Al-4V and other titanium alloys rule the roost in many important CNC machining jobs because they offer something special: incredible strength while being relatively light. This makes all sorts of difference when building parts for jet engines or those tiny but vital surgical instruments. Some research from the biomedical field suggests that titanium plays nicer with our bodies than stainless steel does, cutting down on rejected implants by around 60%. Not bad at all! What really stands out about these metals is how they hold up even when things get hot. We're talking temperatures over 550 degrees Celsius (that's roughly 1022 Fahrenheit) before they start to lose their shape. For stuff like turbine blades in airplanes or heat shields, this kind of performance is gold dust. Plus, titanium doesn't rust easily, which means components last longer in places where saltwater or harsh chemicals would normally eat away at other materials. Think about underwater equipment or implants sitting inside someone's body dealing with all sorts of bodily fluids day after day.

Challenges of Machining Titanium: Tool Wear and Cost Implications

Working with titanium really drives up production costs when compared to aluminum parts. We're talking about roughly double to triple what it would cost for similar aluminum components. The main issue here is titanium's poor heat transfer properties. This causes tools to wear down much faster, and those expensive carbide cutters need replacing about five times as often as they do with aluminum. There are ways around this though. Some shops have had success using high pressure coolant systems which apparently can stretch tool life by around 30 percent. But then there's the whole aerospace angle to consider. These industries demand super tight tolerances, sometimes as small as plus or minus 0.005 millimeters. Meeting those specs means running machines at much slower speeds and investing in special CNC equipment that most general machine shops just don't have lying around.

Industry Paradox: High Cost vs Unmatched Strength-to-Density Ratio

Even though it costs about 8 to 12 times what aluminum alloys do, titanium offers such great strength relative to its weight that planes actually burn 4 to 7 percent less fuel on each flight cycle. Because of this tradeoff, many manufacturers take a mixed approach. They put titanium where it really matters most, like those critical stress points in wing spars, but save money elsewhere by using other materials that work fine for less important parts. The good news is newer machining methods called near net shape are cutting down on wasted material by around 40%. This makes titanium more affordable for expensive CNC components needed in both defense applications and medical devices where performance justifies the extra expense.

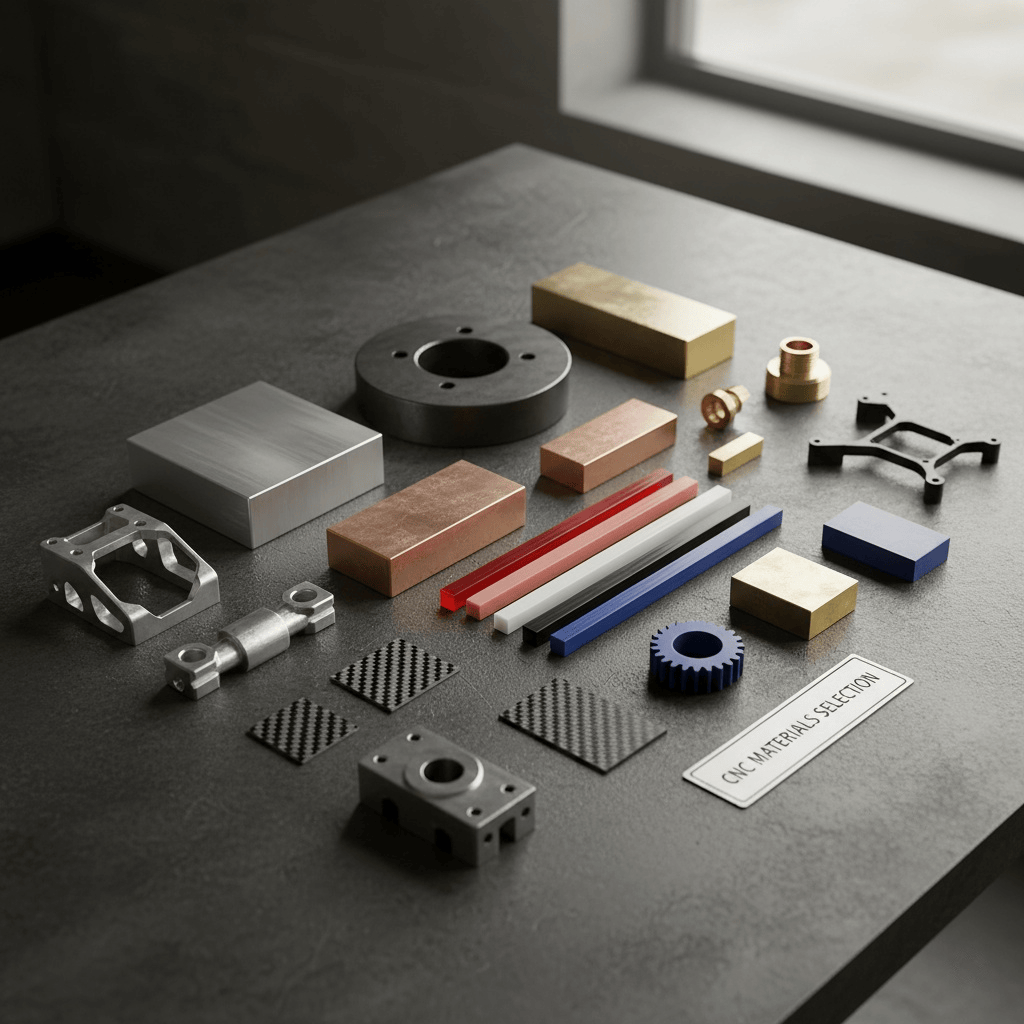

Plastics and Specialized Materials for Precision CNC Machining

Overview of Plastic Material Types Used for CNC Machining

CNC machining today makes good use of engineered plastics that offer both easy machining and solid performance when needed. For everyday applications, thermoplastics such as ABS and POM remain popular choices because they maintain their shape well during manufacturing and work easily on machines. When things get really hot or chemically aggressive, materials like PEEK step in to handle those tough conditions. Many manufacturers pick plastics for CNC components where electrical insulation matters, or when weight is a concern since these materials can be 30 to 50 percent lighter than aluminum. They also help avoid corrosion problems in sensitive areas like medical gear and food processing machinery. Industry reports indicate that about one out of every five CNC prototypes now incorporates plastic instead of metal, mainly to cut down on waiting periods and save money on raw materials.

ABS, PC, PMMA, and POM: Common Plastics for Durable and Precise CNC Parts

- ABS: Ideal for functional prototypes and automotive components due to impact resistance (-40°C to 80°C operating range)

- Polycarbonate (PC): Used in transparent aerospace enclosures and safety shields, with 250 times the impact strength of glass

- PMMA (Acrylic): Machined into optical lenses and signage with 92% light transmittance, though prone to scratching

- POM (Acetal): Delivers low-friction performance in gears and bushings, maintaining ±0.05 mm tolerances under load

These materials require specialized toolpaths to prevent melting during machining. For example, polycarbonate needs coolant-free processing at 12,000–15,000 RPM to avoid stress cracking.

PA, PE, PBT, and High-Performance Plastics Like PEEK in CNC Applications

| Material | Key Property | Industry Use Case |

|---|---|---|

| PA (Nylon) | Wear resistance | Conveyor system components |

| PE | Chemical inertness | Laboratory fluid handlers |

| PEEK | 260°C thermal stability | Satellite thrust chambers |

Aerospace manufacturers increasingly adopt PEEK for CNC-machined fuel system parts, despite costs 8–10 times higher than aluminum. Its UL94 V-0 flammability rating and 15 GPa tensile strength justify the investment in safety-critical applications.

Electrical and Optical Advantages: Copper, Bronze, and Acrylic in Specialized CNC Components

Non-plastic materials fill niche roles in CNC workflows:

- Copper alloys: Machined into EMI/RF shielding components with 95% IACS conductivity

- Phosphor bronze: Used in CNC-formed electrical connectors (50–100 µΩ·cm resistivity)

- Cast acrylic: Precision-milled into light guide panels for displays, achieving Ra <0.8 µm surface finishes

A 2023 study showed CNC-machined acrylic optical components reduce assembly time by 40% compared to molded alternatives in photonics systems, while allowing rapid design iterations.

Strategic Material Selection for CNC Parts: Performance, Cost, and Trends

Good CNC part design really starts when we match the right materials to what they need to do in real world conditions. Take for example a hydraulic valve body that needs to stand up against corrosion problems over time – many engineers would reach for 316L stainless steel because it holds up so well. Meanwhile parts inside MRI machines typically go with non magnetic titanium alloys since those don't interfere with the sensitive equipment. When designers think this way about applications first, they end up wasting less material and creating products that last longer. The numbers back this up too: studies show that picking the wrong material can end up costing companies around 25% extra money just fixing mistakes later on during production runs.

How Application Requirements Dictate CNC Material Choice

Medical implant components prioritize biocompatibility (Ti-6Al-4V) and sterilization tolerance, while automotive turbochargers demand high-temperature resilience (Inconel 718). Engineers increasingly use decision matrices comparing fatigue strength cycles, chemical exposure limits, and thermal expansion coefficients.

Balancing Cost, Machinability, and Performance in CNC Parts

Aerospace manufacturers face the titanium paradox: while raw material costs three times more than aluminum 7075, its strength-to-weight ratio cuts fuel consumption by 12%. Multi-criteria analysis tools now evaluate machining time per alloy, tool replacement frequency, and post-processing requirements.

Trend: Increasing Adoption of Hybrid Materials and Composites in CNC

Carbon fiber-reinforced PEEK blends now achieve 40% higher stiffness than traditional alloys in robotics joints while maintaining CNC compatibility. The hybrid materials market for precision parts is projected to grow 18% annually through 2030, driven by customized thermal conductivity needs, EMI shielding requirements, and sustainable material mandates.

FAQ

Why is aluminum a popular material for CNC machining?

Aluminum is favored in CNC machining due to its excellent strength-to-weight ratio, natural corrosion resistance, and versatility, making it suitable for aerospace and automotive applications.

What are the differences between 6061 and 7075 aluminum alloys?

6061 aluminum is known for its excellent machinability and is used in prototypes and general-purpose parts, while 7075 is stronger, making it ideal for high-stress applications like aerospace components.

How does steel compare to aluminum in CNC applications?

Steel offers higher tensile strength and durability than aluminum, making it ideal for high-stress environments. However, aluminum is lighter and more corrosion-resistant.

What advantages does titanium offer for CNC machining?

Titanium provides a high strength-to-weight ratio, making it perfect for aerospace and medical applications. It also offers superior biocompatibility and corrosion resistance.

Why are plastics used in CNC machining?

Plastics are used for their lightweight, corrosion resistance, and electrical insulation properties, making them ideal for medical, automotive, and electronics applications.

Table of Contents

- Why Aluminum Is a Top Choice for CNC Machining

- Steel and Stainless Steel for Durable CNC Parts

- Why Titanium Is Used for Critical CNC Parts in Aerospace and Medical Devices

- Challenges of Machining Titanium: Tool Wear and Cost Implications

- Industry Paradox: High Cost vs Unmatched Strength-to-Density Ratio

- Plastics and Specialized Materials for Precision CNC Machining

- Strategic Material Selection for CNC Parts: Performance, Cost, and Trends

- FAQ