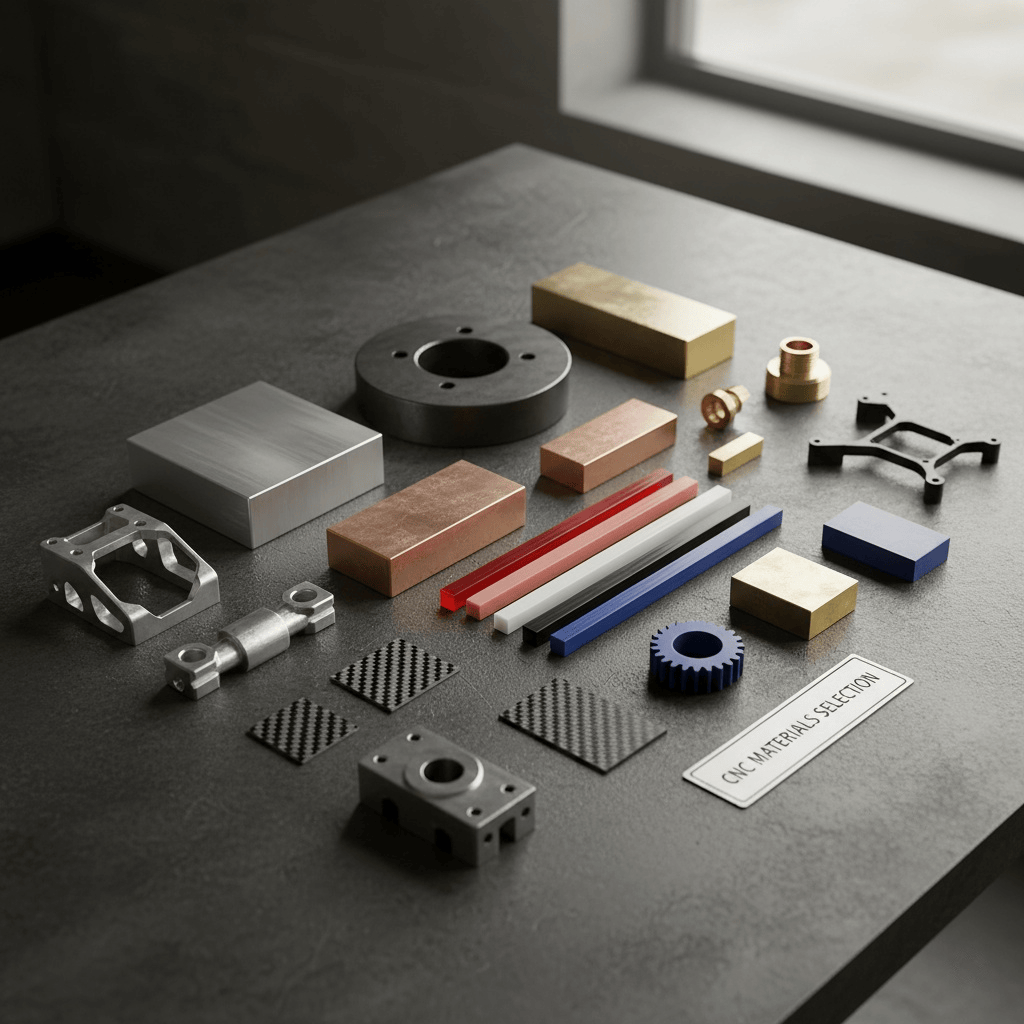

Mene ne Alwuminum ita ce dabi'a mai zurfi don Tsarin CNC

Aluminum ita ce mai yamama a lokacin CNC machining saboda tsauri na yawa kamar abu da ke iya karewa kuma bai ya korosho daidai ba. Fiye da karshen halayyin bukata da suna bukata CNC a fagen aerospace da makonar mota suka yi amfani da aluminum alloys. Wadannan abubuwan samunsa sun kara nisa, daga cikin 40 zuwa 60% satar steel, amma har ma suna taka rawarin gina. Shin dalilin aluminum ta zama mafi kyau don wadannan abubuwa? Tunda tana da coating na oxide a sama, wanda ke wakiltar aluminum daga korosho. Abubuwan da ke dari aluminium suna dauki shekaru girman, masu mahimmanci a wuraren da ke ciki ruhu, kamar wuraren da ke karkashin yanjuwa ko cikin motoci da ke da salti na wutan yanjuwa.

Aluminum Alloys masu amfani a CNC Parts: 6061 vs 7075

| Sarari | alwuminum na 6061 | aluminum 7075 |

|---|---|---|

| Karfin Tension | 40,000 psi | 83,000 psi |

| Kafa | 2.7 g/cm³ | 2.8 g/cm³ |

| Abubuwan Da Ake Amfani Da Su | Makonar mota | Abubuwan haɗi na Aerospace |

| Nau'in Machinability | Mai kyau (95/100) | Mai kyau (75/100) |

6061 yana da wuyan alloy mai amfani ga maɓallin nuna da abubuwan da ke yawa saboda taimakon yadda ya samu da kuduren. Bayan haka, 7075 yana da mahimmanci a abubuwan da ke yanke dama sosai kamar fuselage na wasan zinzamawa, inda tsarin zinc ya bamu karfi mai dubawa biyu shekaru 6061.

Alama kan Tafiya da Kwana

Aluminum tafiya kwana (120–210 W/m·K) ta yi wuya mai tsada kan electronics, ta fitarwa 30% masu damuwa than stainless steel. Kwana ta electrical (35.5×10⁶ S/m) kuma ta yi wuya mai amfani ga busbars da connector housings, ta kare kuduren kwana a cikin tsarin wutar.

Tambaya na Ayyuka: Amfani a Fasaha

Sabon girma na 2023 na satellite mounting brackets yayi amfani da aluminum 6061-T6 ya kara wuya na yankin buƙatar ta 22%, ta ba da damar ci gaba na zaman. Anodizing bayan machina ta kara kwana na sama ta 300%, ta dace shafin fasaha.

Tsammanin: Samar da CNC na Gaskiya ta Amfani da Alwuminam na Sabon Sauke

An kara amfani da alwuminam na sabon sauke a cikin abubuwan CNC ne zuwa ga 52% daga 2020. Wasu tsari mai zurfi yanzu yana sauken 95% na garuruwa bayan samar da ba tare da kuskuren aiki, wanda ya haɗa da standard din ISO 14040 game da cikakken yawa yayin an kara kara kudaden kayan aikin 18–25%.

Fulka da Fulka Mai Ranƙo don Abubuwan CNC masu durability

Alloyoyin fulka sun sarrafa ayyukan CNC na al’ada da ke bukatar durability mai zurfi, tare da fiye da 60% na abubuwan mesinai mai mahimmanci suke amfani da kayan fulka. Masu samar da suna buƙata fulka don bututun shahara ta ozi a cikin albarkatu masu girma.

Strength na mechanical na abubuwan fulka CNC a cikin ayyukan al’ada

Zaɓuɓɓan fulani da ke bayar da CNC suna iya kare tsawon girma, yana samun ƙima ga 2000 MPa a cikin tsarin hydraulic da irin wasu mashegin press. Lokacin da za a yi lafiya zuwa zuwa sharon fulani mai karfin carbon kamar 4140, wadannan abubuwan da ke bayar da yauke ne akan 120% karin yauke dibu da abubuwan aluminum. Don haka muna gona su a wuraren da ke tafiya dama bisa haɗin abubuwan na mines, a cikin abubuwan na automotive, kuma a cikin abubuwan na mashegin construction. Amma don manyin mai amfani da ke duba kuduren, akwai abu da ya kamata a yi wa keke 1045 carbon steel. Yana ba da kyakkyawa ga 580 MPa na yield strength wanne yake nufi abubuwan da ke bayar da su zama masu ci gaba sai dai yake da sauƙin amfani da su. Wannan yana sa ya zama mai sha'awar among companies da ke produce fasteners wanda ke buƙatar wani yanayi da ke tsakanin kyakkyawan aiki da sauya kudi.

Kayan Kankanta na Stainless Steel CNC Components

Abubuwan samun kwiyan stainless steel sun kama da rage biyan kayan ayyuka ne a yankin 40% a wadannan wuraren da suka daki dibensu ga kwayar carbon steel mai amfani da abubuwa. Yaya chromium oxide a cikin grades kuyan 304 da 316 sun ba da:

| Lambar | Tattalin ruwa mai nusa | Takaitaccen Taro (pH <3) | Ceebinta Tsawon Temperature |

|---|---|---|---|

| 304 | Binciken | Kashin daidai | 870°C |

| 316 | Tare daidai | Binciken | 925°C |

Alamomin wasan kwando da alamomin ruwa ke amfani da stainless steel 316 ga abubuwan pompu da suka hada da chlorides da takaitaccen organic acids.

Bayyana: 304 vs 316 Stainless Steel a CNC Machining

Wannan gurbin biyu sun ba da taimakon inganci, amma stainless steel 316 yana da molybdenum 2–3% don kare tsaro a kayan valve na rigai na sama na waya, blades na kimiyyar wasanni, da linings na reactor na samar da chemical. 304 yana da kyau ga mahajirin da ba su da hanyar ciniki sosai, wanda ya yi 65% na abubuwan CNC na kukuna masu amfani.

Tace: Wannan Lokaci Ina Dole Ina Zabuwa Steel Bushe Aluminum ga Abubuwan CNC

Dole ne suka zauna abubuwan ƙima CNC don abubuwan da ke aiki masu girma da yawa da 500 digiri selsiyus, bukatar tafarkar tsauri mai karfi da 400 MPa ko kuma wadanda ke iya ƙaryawa yayin amfani da tasowa. Yanzu alaminiyum zai yi kyau domin rago waje kama da karyawa, saboda kullum ya daki tsaro mai karfi sosai, yana ba da uku shekaru masu karfin tsaro a cikin wasu nau'ikan ayyuka. Ga farafara na wasu manyan sarayen, takamaiman 72% na ma'amalin yankin kullum suna amfani da kullum don abubuwan ƙima CNC a kan manyan ayakin shigarwa, wannan shine saboda baku so ka iya kuskuren sake don neman rago waje.

Mene ne Titanium an amfani da ita don abubuwan CNC masu mahimmanci a cikin wasan fage da kayan dawo

Ti-6Al-4V da sauran alloy na titanium suna ƙauyacen a cikin yawa daga cikin masu mahimmanci a CNC saboda suna ba da wani abu mai tsada: hankali mai zurfi yayin da suke lekere. Wannan yana iya canzawa a kowane nau’i na kayan amfanin injin jet ko wasu alkaruɓɓan kayan amfani masu mahimmanci. Wasu bincike daga fanni na biomedical suna nuna cewa titanium yana amfani da badinmu sosai karfi duk da stainless steel, yana rage waɗanda ke soke implants ne a kama zuwa 60%. Babu zuci! Abin da ya fara rungume a cikin wannan gurbin shine yadda suna tafiye ta hanyar yake. Mun yi imanin shigoggiyan da suka fi 550 daraja Celsius (wato kamar 1022 Fahrenheit) kafin su fara kawo shape su. Don abubuwan kamar turbine blades a cikin yanjuwa ko heat shields, wannan nau’in ayyukan sana’o ita ce mai kyau. Sai kuma, titanium bai sami karfin rust ba, wacce taimaka kayayyakin su kasance sosai a wuraren da ke samun ruwa mai namda ko chemicals mai sharara wadanda za su fara share wasu gurbi. Dua zuwa kayan aikin da aka fitowa a juyin ruwa ko implants da suka canza a cikin jiki mai amfani da duk iyakokin badin yau zuwa yau.

Alaƙa na Gudan Hewa na Titanium: Rukunin Karamar Aiki da Makamashi

Aiki da titanium yana naya kariƙe mai zurfi masiraun bayarwa a goyon bayarwa na aluminum. Muna yi imanin karuwa gaba dubu uku ne ga abubuwan titanium wanda suke daidai da abubuwan aluminum. Abubuwar muhimmanci shine alaƙar titanium da ke kyau na kwayoyin hankali. Wannan yana haɗawa cutters su kasance masu dadi, sai dai kuma cutters na carbide masu biyan farashin su sabunta miliyar gaba dubu uku a lokacin aikin da aluminum. Har ma, akwai hanyoyin kula da wannan batun. Wasu wasan tattalin arziki sun sami nasara a amfani da tsarin coolant mai girman pressure wanda zai iya kara cirewa ta cutters takamatan 30%. Amma har sa, akwai batun aerospace. Wasu sarayen wannan yankin ke richa zuƙaitacciyar iyaka, yana iya kasancewa kamar plus ko minus 0.005 millimeters. Yanzu za a iya samun wadannan abubuwa ta runon bukata ayyukan aƙalla kuma ina buƙatar samun abubuwan CNC masu lafiya wanda baza a halartar a wasan tattalin arziki.

Jujjuyar Ayyuka: Kimafofin Karfe da Rabi Ƙima tsakanin Girma da Densiti

Neuwa ya samu kimafofi gama 8 zuwa 12 shekaru kamar alikero, titauniyam yana ba da girmama mai zurfi sosai ga wuta kamar yadda zai barcin 4 zuwa 7% karfin kwayoyin na farko. Saboda wannan maye lafiya, masu amfani da dukkanin ayyukan yana amfani da hanyar fasaha. Suna saka titauniyam a wuraren da suke da mahimmanci sosai, kamar wadannan alamar zurfa a cikin wing spars, amma suna kare pulaite a wasu wuraren ta amfani da wasu abubuwan da suke aiki kyautu ga abubuwan da ba mahimmanci ba. Albarka ce ne, akan hanyoyin nau'ikan ganoƙi masu zaman kansu (near net shape) suna kawowa karfin kayan aikin da ba shi da amfani game da sakamako ~40%. Wannan yana sa titauniyam ya zama mai damar fitowa don CNC kayan aikin da ke bukatar cikakken ayyuka a cikin ayyukan dutsen kasa da kayan gwamnati inda ayyukan zai sa karfin.

Plastik da Abubuwan Masu Ilo da Zaman Lahira don CNC Ganoƙi

Tafarka ta Fassarar Nu'ukan Plastik da aka amfani da su don CNC Ganoƙi

Yanayin CNC yanzu yana amfani da kwayoyin masaukin da ke ba da saukin tsarin da kuma aiki mai zurfi lokacin da ake bukata. Ga alamar everyday, thermoplastics kamar ABS da POM sun zama zauna masu sha'awar ayyuka saboda suna tsamman datsi akan yanayinsa yayin samawa kuma su aiki ne sai yawa kan abubuwan ƙima. Lokacin da hali sun faruwa masu hankali ko masu kimika, abubuwan masaukin kamar PEEK sun shigo kuɗi waɗannan halayyen masu hankali. Manyaufoi masu sauƙi suna zaunawa kwayoyin masauki ga abubuwan CNC inda tasawa ta elektrik tare da mahimmanci, ko inda masa tuntuba shine dalilin shiga saboda wadannan abubuwan masauki za su iya kasancewa 30 zuwa 50% ka waje karfe na aluminum. Suna kuma taimakawa wajen warware matsalolin korosi a wuraren masu hankali kamar kayan medisini da kayan aikace-aikace na abinci. Kirafojin al'amuran sun nuna cewa kusan wani dari daya kusa da biyar daga CNC yanzu yana ƙara kwayar masauki sashen metal, kamar yadda aka ke so ya gogonci lokaci da kuma ya kasa kuduren kayan tarbiyya.

ABS, PC, PMMA, da POM: Kwayoyin Masauki Masu Amfani Ga Abubuwan CNC Masu Zurfi Da Sauni

- ABS : Maimakon sadarwa na iya amfani da shi don samunin nau'ikan aikace-aikace da abubuwan tsere na otomatik saboda tafiya (-40°C zuwa 80°C yanzu)

- Polycarbonate (PC) : Ana amfani da shi a cikin aljana mai dubbuwa na sama da dandamalin tsaro, wanda ke 250 karatu tafiya na glass

- PMMA (Acrylic) : An buwar ilimin kula da alamar tare da 92% kewayon ruhu, amma yana da kyau zuwa kankara

- POM (Acetal) : Yana ba da aiki mai karamin gudu a cikin girman da bushings, yana barin kwayoyin ±0.05 mm a lokacin da yake juyawa

Wadannan abubuwa suna bukatar yanayin mahada daidaita don mutum ya yi wa kai zuwa sa hannu lokacin buwar. Misali, polycarbonate suna bukata abubuwan da ke sauƙi a 12,000–15,000 RPM don zama ba tare da kashewa.

PA, PE, PBT, da Plastics mai inganci kamar PEEK a cikin CNC Applications

| Abu | Abubuwar muhimmi | Amfani na Tsarin Ibi |

|---|---|---|

| PA (Nylon) | Tasowa zuwa kan kaiwa | Abubuwan tsin abincin conveyor system |

| Pe | Zaure mai kimantawa | Manken ruwa na laboratori |

| PEEK | 260°C sabon taimakawa | Chambers na satelit na gudu |

Masu amfani da PEEK a fagen aerospace sunke karfi suka amfani da PEEK don abubuwan tsin yanar gizo masu CNC, domin biyan kuɗi mai yawa 8–10 lokuta fiye da aluminium. Nau’in kuɗi na UL94 V-0 da kama’adin tensile na 15 GPa ya sa biyan kuɗi aikawa a abubuwan muhimmi.

Albarkatun Karkashin da Na Gudummawa: An gina Alkawari, Bronze, da Acrylic a cikin Komponen CNC masu amfani mai goyon

Abubuwan da ba plastik bane su na iya ayyukan kamar yadda suka hausa a cikin tsarin CNC:

- Alloyolin alkawari : An buwar su zuwa komponen shielding EMI/RF tare da 95% IACS conductivity

- Phosphor Bronze : An amfani da su a cikin wasan kirkirin abubuwan da ke sauyawa (50–100 µΩ·cm resistivity)

- Acrylic manta : An buwar su bisa fahimta zuwa sarufan gidan ruwa don shafuka, taka rawar Ra <0.8 µm

Tambayoyin shekarin 2023 ya nuna cewa abubuwan optical acrylic da aka buwa CNC sun kama lokacin tattara ta hanyar 40% dibdas daga cikin irin da aka mold a cikin tsarin photonics, yayin da su ba da damar canzawa kan nazarin sabada.

Zauren Zaurena na Abubuwa don Komponen CNC: Aiki, Kusurwa, da Manazarta

Fara da kyau na nuna CNC ya dawo yayin da mu kirkirin kayan aikin da suke bukata cikin halayyin yanzu. Don misali, badna gidan injin hydraulic wanda yake tafiya da rashin kai tsautsa a makonar lokaci – irin abokan ilimi masu karfin 316L stainless steel saboda yake tafiya da shi sosai. A wani makamashi, kayan aikin cikin masin MRI suna amfani da alloys titanium mara magnetic saboda ba su yanke alaƙa da kayan aiki mai hankali. Lokacin da wasan masu kirkira suna gedan haka game da ayyukan farko, suna gudanawa kayan aikin karami kuma kirkiran abubuwan da ke dauki lokaci. Adadin bayani yana kama da wannan: labarai suna nuna cewa zaɓen kayan aikin mara kyau zai iya kwaraba masu siyarwa takaitaccen 25% kadauka don sake sauya kuskuren a lokacin girma.

Yaushe Suje Kamar Yadda Ayyukan Suna Nuna Zabenta Na CNC

Abubuwan da keke tsere cikin jiki suna bukar kama da rashin zama babban (Ti-6Al-4V) da kama da sauye zuwa mai kyau, yayin da abubuwan da keke turbocharger na otomatik suna bukar kama da shakatawa mai girma (Inconel 718). Masu ingineer ana amfani da matrices na hankali wato yawan rukuƙun gudu, iyaka zuwa ma'addu, da ko'ina’i masira mai tafiya.

Taimakawa Kusurin, Samun Ilimi, da Ayyukan Abubuwan CNC

Masu kirkiran sama dan sama sun shaƙalci da albabbin titanium: yayin da kusurin raw material ta uku shekaru karshen aluminum 7075, ko'ina'insa na girma zuwa wucewa ya kara kuma 12%. Alamar takaitaccen takai yanzu sun yi muhakin lokacin machining per alloy, yanayin canza wasan, da buƙatar binciken bayanin.

Tsammi: Tafiye-tsanyar Amfani da Abubuwan da ke biyu da abubuwan composite a cikin CNC

Yankin PEEK da ke na tsayin karbon bayan kawo 40% yawa a alƙawari ga alloys na musamman a jerin robotics yayin da suka tsaya da compatibility CNC. Ana buƙaci yankin abubuwa na hybrid don abubuwan masu mahimmanci zai darar 18% kowace shekara har zuwa 2030, wanda ya sa shigar da buƙatar conductivity na goroberen, buƙatar sadarwa EMI, da gurbin abubuwan da ke tsada.

Tambayoyi Masu Yawan Faruwa

Mene ne aluminum ita ce abubuwa mai sha'awar da ke amfani da shi cikin CNC?

Aluminum ta godon in CNC machining saboda mafi kyau na girma-daga-tsaki, dana kuzarti, da mutuwalin amfani, wanda ke kama da aerospace da automotive applications.

Wanne ne farkoɗin bayan 6061 da 7075 aluminum alloys?

aluminum na 6061 tana fi sanya da machinability mafi kyau kuma ana amfani dashi cikin prototypes da abubuwan masu amfani, yayin da 7075 ita ce mafi girma, wanda ke kama da abubuwan da ke da girman pressure kamar abubuwan aerospace.

Yaushe steel ta ke da alaƙa da aluminum cikin CNC applications?

Fulka ya ba da tsauraran tare da kama'a fiye zuwa ga aluminum, wanda ya sa ya zukaka har zuwa ga alamun dutsen. Amma aluminum ita ce babban kama'a da kaiwa.

Wanne ban sha'awa ke kawo titanium don CNC machining?

Titanium ta ba da yankin tsauraran zuwa kaiwa, wanda ya sa ta zukaka har zuwa ga alamun sama da ayyukan tashoshin tattaunawa. Ta kuma ba da kyakkyawan kama'a da kaiwa da kama'a.

Mene ne nuna plastic a cikin CNC machining?

Plastic ana amfani da su don kaiwa su, kama'ar kaiwa, da kuma kama'ar electric, wanda ya sa su zukaka har zuwa ga tashoshin tattaunawa, otomatik, da elektronik.

Teburin Abubuwan Ciki

- Mene ne Alwuminum ita ce dabi'a mai zurfi don Tsarin CNC

- Fulka da Fulka Mai Ranƙo don Abubuwan CNC masu durability

- Mene ne Titanium an amfani da ita don abubuwan CNC masu mahimmanci a cikin wasan fage da kayan dawo

- Alaƙa na Gudan Hewa na Titanium: Rukunin Karamar Aiki da Makamashi

- Jujjuyar Ayyuka: Kimafofin Karfe da Rabi Ƙima tsakanin Girma da Densiti

-

Plastik da Abubuwan Masu Ilo da Zaman Lahira don CNC Ganoƙi

- Tafarka ta Fassarar Nu'ukan Plastik da aka amfani da su don CNC Ganoƙi

- ABS, PC, PMMA, da POM: Kwayoyin Masauki Masu Amfani Ga Abubuwan CNC Masu Zurfi Da Sauni

- PA, PE, PBT, da Plastics mai inganci kamar PEEK a cikin CNC Applications

- Albarkatun Karkashin da Na Gudummawa: An gina Alkawari, Bronze, da Acrylic a cikin Komponen CNC masu amfani mai goyon

- Zauren Zaurena na Abubuwa don Komponen CNC: Aiki, Kusurwa, da Manazarta

- Tambayoyi Masu Yawan Faruwa