CNC turning plays a central role in making precision shafts, giving builders speed and the kind of accuracy old-school methods can't match. In this post, we break down what CNC turning really means, look at its perks and common uses, and peek at the tech that keeps the spindles spinning. As more industries ask for top-grade parts, knowing how CNC turning works can help factories meet those tough goals.

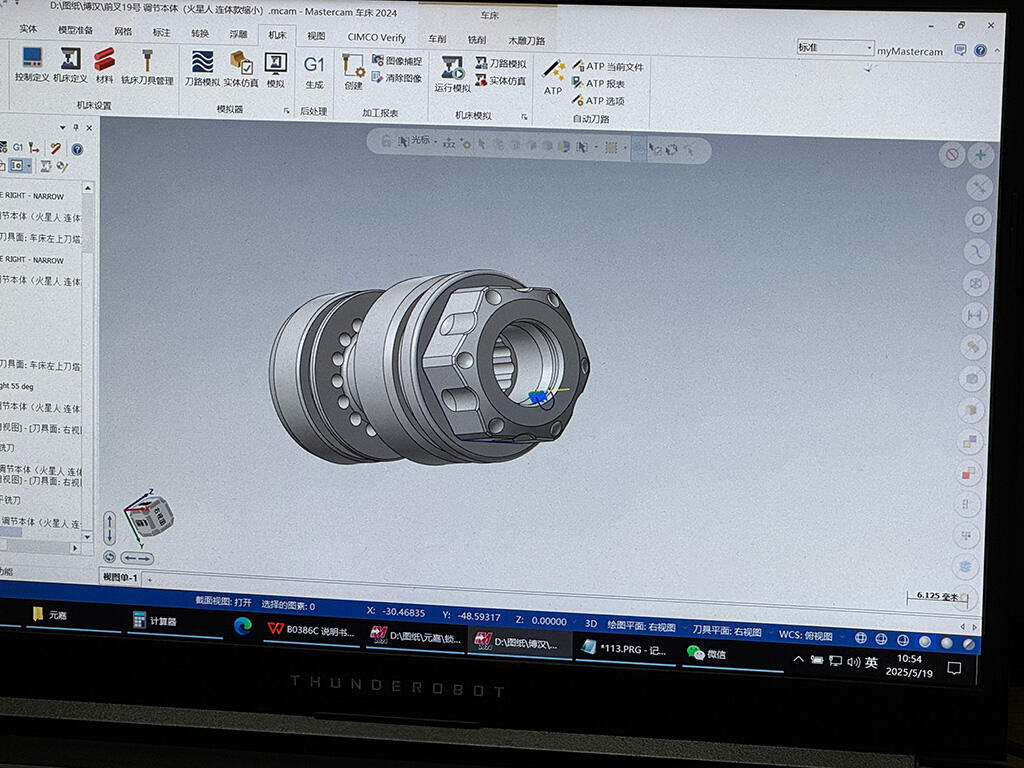

First, lets talk about the tech at the heart of the process. Computer Numerical Control, or CNC, has flipped manufacturing on its head by moving tool control from hands to code. With CAD (Computer-Aided Design) software, engineers draft a step-by-step digital plan that the lathe reads like sheet music, directing every cut, speed, and feed. That bit of automation trims both errors and clock time, so orders can leave the shop sooner.

When it comes to shafts, tiny mistakes translate into big failures, so every decimal counts in fields like automotive, aerospace, and medical gear. Parts often need to fit within a few thousandths of an inch, and CNC turning is built to nail those limits. Add high-speed spindles and specialist cutting tools, and chips fall cleanly, waste shrinks, and the end product earns the best quality stickers.

Picking the right material is another key step in CNC turning. Shops can run jobs in metals such as aluminum, steel, and titanium, plus many grades of plastic and fiber composite. Because each substance cuts and behaves differently, knowing the pros and cons lets a team match the material to its job. Aluminum machines fast and stays light, but titanium gives aircraft and medical parts strong, rust-proof skin.

That same flexibility means CNC turning makes more than shafts. Gears, pulleys, bushings-even custom fasteners-roll off the lathe and into assembly lines, proving how broad the process really is. As new machines, sensors, and designs keep arriving, CNC turning will keep growing, planting itself firmly in tomorrows factory toolbox.

CNC turning is still the go-to method when makers need accurate shafts, and thats mainly because modern machines can handle many materials. As customers ask for cleaner, stronger parts, factories have to keep up with new tools and ideas in CNC work. Thanks to rising robots and smarter metals, the outlook for CNC turning is bright; we can expect even finer accuracy and faster production.