CNC Turning vs Milling: Key Differences Explained

CNC turning and milling sit at the heart of modern manufacturing. Knowing how they differ can help businesses boost output, save costs, and raise product quality.

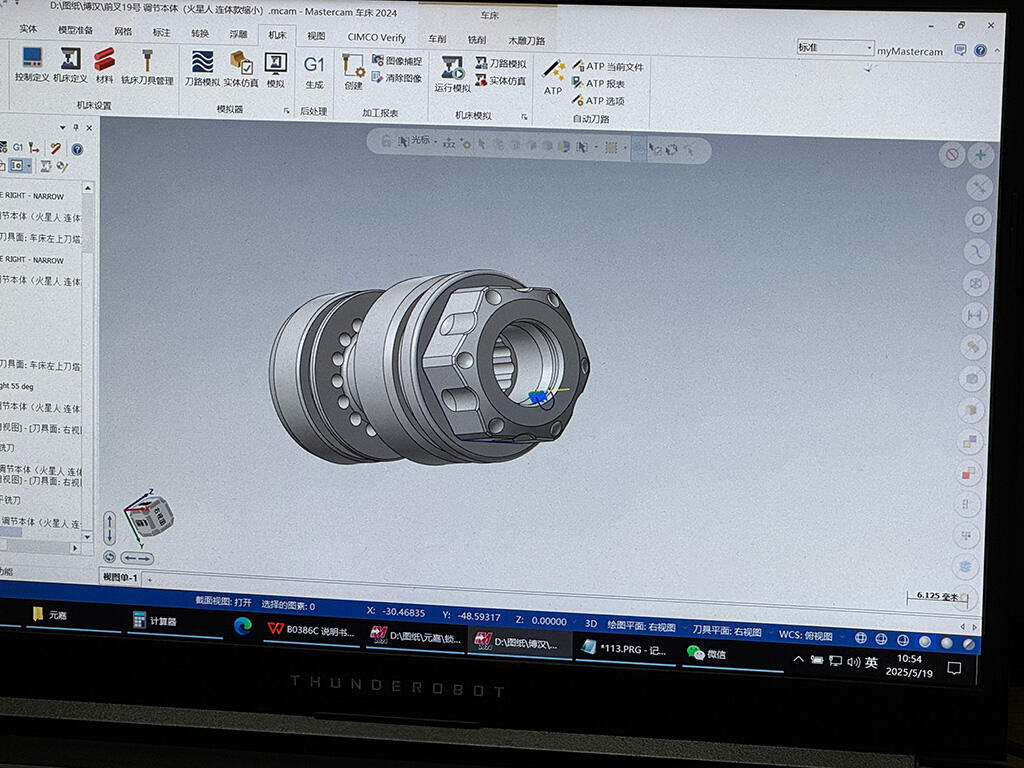

CNC Turning at a Glance

CNC turning is a subtractive process in which a workpiece spin...

View More